LAMOTEK Insights | The Pros and Cons of 3D Printed Molds

01 3D Printing Supports the Upgrading of Mold Manufacturing Technology

As an advanced manufacturing technology, 3D printing has made significant technological progress in recent years, with deep applications across various industries. Among these, SLM (Selective Laser Melting) technology, being the most mature and commercially viable 3D printing technique, has seen extensive use in aerospace, medical, nuclear power, molds, and industrial manufacturing.

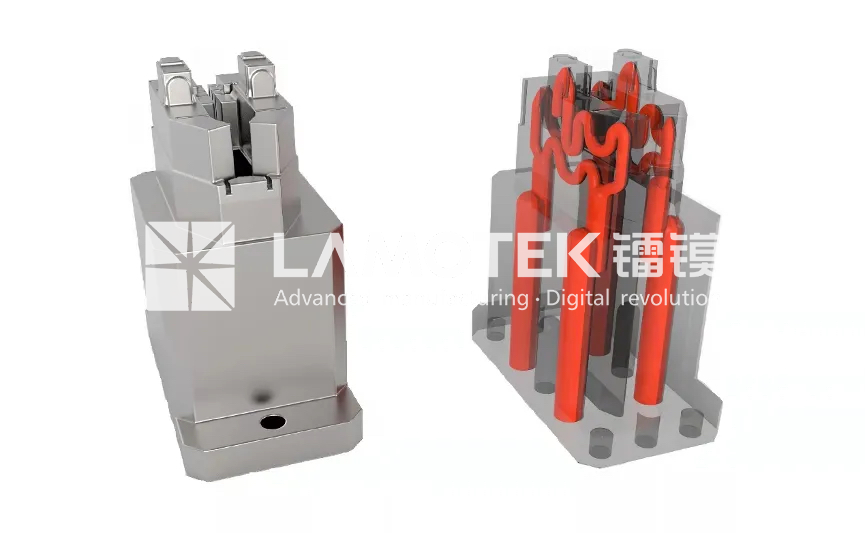

Unlike key industries like aerospace and nuclear power, which are heavily regulated, the mold industry is characterized by a large market size and intense competition. Industry players compete based on comprehensive hard strengths such as technology, products, and services. In this fully market-driven competition, the company that first achieves an upgrade in mold technology and provides downstream industries with products that offer better “cost-performance” and “quality-price ratios” can gain a competitive advantage. SLM technology has unique advantages in areas such as conformal cooling channels, complex mold manufacturing, and exhaust structures, making it an important technological direction for mold upgrading in recent years, attracting the attention of many mold customers.

Unlike key industries like aerospace and nuclear power, which are heavily regulated, the mold industry is characterized by a large market size and intense competition. Industry players compete based on comprehensive hard strengths such as technology, products, and services. In this fully market-driven competition, the company that first achieves an upgrade in mold technology and provides downstream industries with products that offer better “cost-performance” and “quality-price ratios” can gain a competitive advantage. SLM technology has unique advantages in areas such as conformal cooling channels, complex mold manufacturing, and exhaust structures, making it an important technological direction for mold upgrading in recent years, attracting the attention of many mold customers.

02 Customer Concerns: Is the Performance Adequate?

However, unlike other products, molds are expensive production tools in the manufacturing industry, with very high requirements for service life. For example, injection molds can last for hundreds of thousands to even millions of cycles, while die-casting molds, subjected to harsher conditions, generally require a lifespan of tens of thousands of cycles or more. This leads many customers to question: can 3D printing technology, as an emerging manufacturing method using new materials developed based on printing processes and forming solids through discrete stacking, really meet the stringent requirements for molds?

03 Why 3D Printed Molds Can Meet Performance Standards

To answer this question, we must understand what determines performance.

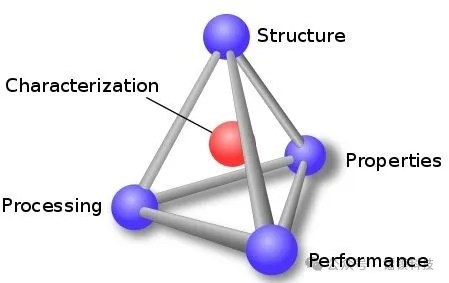

In materials science, there is a classic tetrahedral relationship known as "Structure-Process-Material Properties-Application Performance," which describes the intrinsic relationships among materials. It can be said that the performance of components is determined by the material properties used in the production process, the manufacturing technique, and the resulting microstructure. The influence of the process on performance ultimately reflects in the microstructural organization of the component. Therefore, under similar intrinsic material properties, the final performance exhibited depends on the type of microstructure formed.

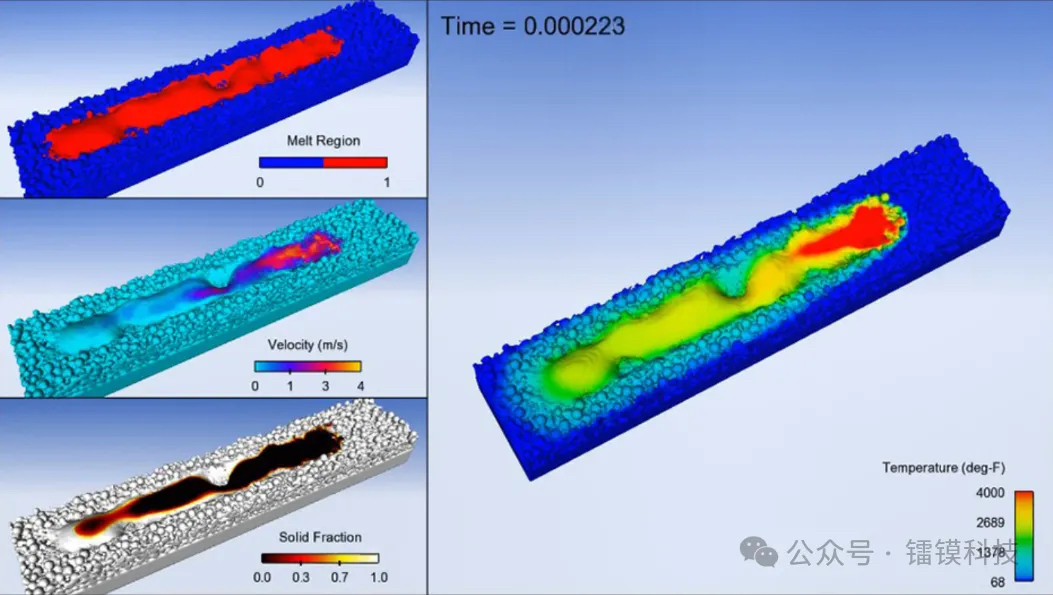

Moreover, because the diameter of the laser spot is typically below 100μm, it forms small molten pools, with the melting and solidification process of each small pool completed in an instant, significantly reducing the heat-affected zone. This can result in microstructural features similar to equiaxed grains, leading to fine-grain strengthening effects. Consequently, some mechanical properties can ultimately reach levels comparable to forged components.

In addition, for mold steels with phase transformations, further heat treatment processes can be employed to release residual stresses from the printing process and adjust the material's microstructure, ultimately achieving performance that meets mold usage requirements.

In addition, for mold steels with phase transformations, further heat treatment processes can be employed to release residual stresses from the printing process and adjust the material's microstructure, ultimately achieving performance that meets mold usage requirements.

Of course, the actual performance of 3D printed molds also relates to factors such as the materials used by suppliers, their processes, design schemes, and maintenance. When applying 3D printing suppliers, mold customers need to consider their own product characteristics and production requirements, and choose reliable, high-quality service partners or suppliers.

LAMOTEK has been deeply involved in the 3D printing industry for over a decade, focusing on the industrial application of molds. Our company has developed innovative achievements in specialized materials, processes, standard designs, and quality services for the application of 3D printing technology in molds. We can provide customers with comprehensive solutions and assurances across all aspects, from mold material selection and design process formulation to daily maintenance and after-sales service. In the future, LAMOTEK will continue to uphold original intention, provide excellent service, and help more mold customers achieve success.